PLC, HMI and Data Acquisition

PLCs (Programmable Logic Controllers), HMIs (Human Machine Interfaces) and data-collecting systems are at the heart of modern industrial automation, boosting efficiency, dependability and control in a variety of industries. These systems are crucial for managing and monitoring industrial operations, as well as providing seamless integration and real-time communication among various industrial components. The technological synergy between PLCs, HMIs and data acquisition systems is crucial for establishing operational excellence, optimizing production and ensuring the safety and dependability of industrial operations.

Lascar Electronics, a leader in providing advanced monitoring and display solutions, fulfils the particular requirements of industrial automation with a wide range of devices designed to enhance the capabilities of PLC, HMI and Data Acquisition systems. By integrating Lascar’s unique solutions, industries can attain greater levels of control and monitoring precision, ensuring that their operations are more efficient, adaptive and aligned with the evolving demands of the industrial landscape. This, in turn, creates an ongoing development and innovation environment, moving the industry forward in an era of rapid technological growth.

Products and their Applications

Lascar Electronics is at the forefront of innovation, developing products that are critical in optimizing PLC, HMI and Data Acquisition systems. Our solutions are intended to improve control, provide complete real-time monitoring and enable precise and fast data collecting across a wide range of applications.

Lascar Electronics’ commitment to technical innovation is shown in our diverse and unique product line. Each product is carefully designed to deliver dependability, accuracy and adaptability while meeting and exceeding the criteria of specialized sectors such as PLC, HMI and Data Acquisition.

PanelPilotACE Display Modules

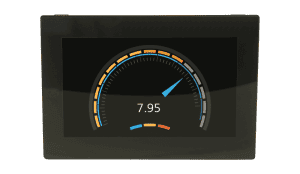

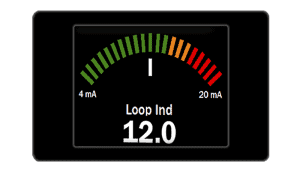

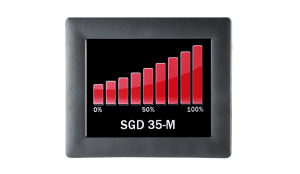

These versatile and adaptable display modules are essential for HMI applications because they provide real-time monitoring, user-defined warnings and optimal interaction with various automation systems, assuring efficiency and adaptability.

-

PanelPilotACE

-

PanelPilotACE

-

PanelPilotACE

EL-USB Data Loggers

Accuracy and precision are critical in data collecting and our EL-USB Data Loggers are built to excel in both. These devices are essential for accurately recording environmental data, which is required for informed and strategic decision-making.

-

Temperature Data Loggers

-

Temperature Data Loggers

-

Temperature Data Loggers

EasyLog Cloud

Lascar’s EasyLog Cloud is a comprehensive data management solution that provides safe and remote data access. This platform is essential for real-time monitoring, data processing and data integrity in PLC, HMI and other applications.

Why Choose Lascar Electronics?

Opting for Lascar Electronics as your technology partner means choosing a blend of innovation, reliability and customer-centric solutions. We are dedicated to enhancing and empowering your systems with our advanced and diverse product range, along with unparalleled support.

Innovative Approach: Our commitment to innovation is reflected in our product portfolio, which includes the adaptable PanelPilotACE Display Modules, the extremely precise EL-USB Data Loggers and the complete EasyLog Cloud platform, all of which are designed to fulfil the diverse needs of PLC, HMI, and Data Acquisition.

Reliability and Precision: Our product development is based on dependability and precision. We ensure that our products give accurate data and seamless control on a constant basis, contributing to the optimal operation and performance of your systems.

Expert Support and Guidance: Our team of experienced professionals is passionately committed to delivering exceptional support and assistance, ensuring that you maximize the benefits and capabilities of our products in your various fields.

Partnering with Lascar Electronics is an investment in a relationship that values excellence, innovation and customer satisfaction. Through our cutting-edge solutions, dependable products and expert support, we are dedicated to elevating your Programmable Logic Controllers (PLC), Human-Machine Interface (HMI) and Data Acquisition systems.

Case Study

Dive further into the world of real-world applications to learn how clients from many sectors have successfully integrated Lascar Electronics’ revolutionary PLC, HMI and Data Acquisition systems. Our case studies offer useful insights into the practical uses, numerous benefits and revolutionary influence of our technologies in several circumstances and industries.

PanelPilotACE Display: Data Acquisition & Control

Mackie Transmission

Established 40 years ago, Glasgow-based Mackie Transmission specializes in the re-manufacturing of automatic and manual transmissions for cars and larger commercial vehicles. Quality benchmarking and reducing product failure during re-manufacture are key and so to help set and maintain these, the company developed its own hydraulic test machine to test the integrity of hydraulic circuits on an automatic transmission.

The machine allows the operator to compare the actual values of the transmission they are working on, to the values it should be if in full working order, by pumping automatic transmission fluid into the transmission and providing pressure and flow readings.

These readings indicate whether a hydraulic circuit in the automatic transmission is in a serviceable condition or if there is a potential leak in the circuit.

The company’s first test machine was fitted with physical buttons and analogue gauges to show these values but realizing technicians needed a faster and easier interface, the machine was recently re-designed using Lascar’s 7 inch, capacitive, touchscreen display – the SGD 70-A.

Large and easy to read, the SGD 70-A is used to switch various solenoids and a pump motor through solid state relays and then display data from a flow and pressure transducer, in turn allowing the user to compare those readings with known good values. Clearer and more accurate data allows more precise diagnosis, which in turn leads to a higher product quality and a decreased use in warranty by the end customer.

Featured Products

-

PanelPilotACE

-

PanelPilotACE

-

PanelPilot M