Food Temperature Monitoring

The need for precise food temperature monitoring cannot be highlighted enough in today’s fast-paced food business. Monitoring food temperature is an important part of assuring food safety and quality. Keeping food at the correct temperature during storage, preparation and serving is critical for avoiding foodborne illnesses and retaining the freshness and flavor of foods. Maintaining precise control over food temperatures is critical to following regulatory standards and satisfying your clients, whether you run a restaurant, manage a catering business, or operate a food production facility.

This monitoring protects the integrity of your culinary creations, guaranteeing that they are delicious and safe to consume. Businesses can optimize their food temperature monitoring operations with cutting-edge technology and dependable solutions, providing peace of mind and higher quality to both cooks and consumers.

Wide Selection of Expert Goods

Lascar Electronics carefully creates a number of product lines that are specifically designed to suit the highly sensitive demands of Food Temperature Monitoring.

EasyLog USB Data Loggers

These compact and straightforward instruments are essential for recording temperature levels in a variety of food situations, such as storage and transit. They play a critical role in keeping perishable foods within safe temperature thresholds, preserving food quality and limiting health concerns.

-

Temperature & Humidity

-

Temperature & Humidity

-

Temperature & Humidity

EasyLog WiFi Series

This series is crucial for locations requiring continual examination, such as refrigerators, freezers and food storage facilities, because it provides the ease of real-time monitoring and warnings for both temperature and humidity. The wireless feature enables remote monitoring and prompt actions, ensuring food product integrity.

-

Temperature & Humidity

-

Temperature & Humidity

-

Temperature Data Loggers

Cold Chain Logistics Loggers

These loggers, designed to meet the strict requirements of cold chain management, ensure the safe transit of temperature-sensitive food goods from manufacture to consumption. They offer precise temperature monitoring and data logging, which are critical for adhering to food safety requirements and preserving the quality of perishable foods.

-

Cold Chain Logistics

Cold Chain Logistics, Temperature Data Loggers

US$246.99 ex. taxPack of 10 Chilled Goods Data Logger with AlarmsAdd to cart -

Cold Chain Logistics

Cold Chain Logistics, Temperature & Humidity

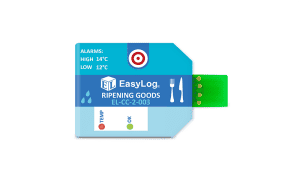

US$391.99 ex. taxPack of 10 Ripening Goods Temp & RH LoggerAdd to cart -

Cold Chain Logistics

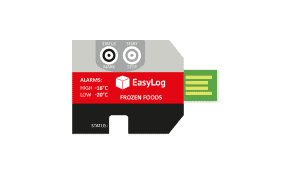

Cold Chain Logistics, Data Loggers, Temperature Data Loggers

US$277.99 ex. taxPack of 10 Frozen Goods Data LoggerAdd to cart

Data Security: 21CFR Compliant Loggers

Data Security: 21CFR Compliant Loggers

If your data records must be secured and are subject to external audit validation, look into our 21CFR-compliant loggers. These loggers follow the standards set by 21CFR Part 11, a global standard for assuring the trustworthiness, reliability and comparability of electronic records to signed paper records. The EasyLog 21CFR series is intended for usage in a Part 11-compliant environment.

-

Temperature Data Loggers

-

Temperature & Humidity

-

Data Loggers

Data Loggers, Temperature Data Loggers

US$126.49 ex. tax21CFR Temperature Data Logger with USB (0 to +200°C)Add to cart

Why Choose Lascar Electronics?

Choosing Lascar Electronics for Food Temperature Monitoring is opting for a blend of innovation, reliability and industry insight:

Industry-Specific Expertise: Lascar Electronics brings to the table a wealth of specialized knowledge and understanding of the unique challenges and compliance standards of the food industry. This expertise translates into products and solutions that are not only reliable but also precisely aligned with the specific needs of food temperature monitoring.

Cutting-Edge Innovation: The commitment to technological advancement is evident in every Lascar product. Designed with the user in mind, the solutions offer not just accuracy in monitoring but also ease of use and clear, actionable data visualization, which are essential in maintaining and ensuring food safety standards.

Adaptable and Scalable Solutions: Understanding the varied nature of the food industry, Lascar offers a range of products that can be customized to suit different environments and requirements. Whether you are a small eatery or a large food processing unit, there is a Lascar solution that can be tailored to meet your needs.

Unparalleled Customer Support: Lascar Electronics distinguishes itself with a dedicated customer support team that is always ready to assist. From resolving queries to offering guidance on product utilization, the support team ensures that every user experience is seamless.

The combination of these attributes makes Lascar Electronics a trusted and preferred partner in the realm of Food Temperature Monitoring, ensuring the safety, quality and compliance of food products across the supply chain.

Case Studies

To further illustrate the practical applications and benefits of Lascar Electronics in Food Temperature Monitoring, we will explore real-world scenarios in the upcoming case study section. These detailed narratives will delve into specific challenges, strategic implementations of Lascar’s technology and the successful outcomes in maintaining food safety and quality.

WiFi: Chef’s Magic Ingredient

Temperature and humidity monitoring with Royal Oak Catering

The Royal Oak pub in the New Forest adopted EL-WiFi temperature and humidity sensors for compliance with food safety regulations. Pub Manager Richard Bird installed these sensors in storage and kitchen areas, automating temperature monitoring to ensure HACCP compliance. This saved time and reduced the risk of human error during food preparation. Notably, the sensors also detected a faulty freezer thermostat, preventing potential stock loss and significant costs for the business.

WiFi: Fuch Cereals

WiFi Temperature & Humidity Monitoring

Fuchs Cereals, a leader in cereal production for over 80 years, distributes its products to over two dozen countries globally, emphasizing premium quality and taste. To meet stringent quality and regulatory standards, they required efficient environmental monitoring, particularly for temperature control in refrigerators and freezers. Previously, manual checks were time-consuming and prone to errors. Seeking a cost-effective and efficient solution, they adopted Lascar’s EasyLog WiFi sensors, allowing them to access real-time data remotely via the Cloud. This scalable and flexible system provides continuous monitoring, saving time and offering long-term cost benefits. Fuchs plans to expand its use of EasyLog WiFi solutions across the company.

Featured Products

-

Temperature & Humidity

-

Cold Chain Logistics

Cold Chain Logistics, Temperature Data Loggers

US$246.99 ex. taxPack of 10 Chilled Goods Data Logger with AlarmsAdd to cart -

Cold Chain Logistics

Cold Chain Logistics, Temperature & Humidity

US$391.99 ex. taxPack of 10 Ripening Goods Temp & RH LoggerAdd to cart -

Temperature Data Loggers

-

Cold Chain Logistics

Cold Chain Logistics, Data Loggers, Temperature Data Loggers

US$277.99 ex. taxPack of 10 Frozen Goods Data LoggerAdd to cart -

Temperature Data Loggers