Sanitary Designs

Founded in 2001, CheezSorce and Sanitary Design Industries (SDI – equipment division of CheezSorce) provide a range of consultancy and environmental control systems for innovative cheese makers and dairy processors across North America.

Under the management of veteran cheese consultant Neville McNaughton, the company assists numerous new entrants, midsize and micro dairy businesses in the growing market of high quality artisan cheese production.

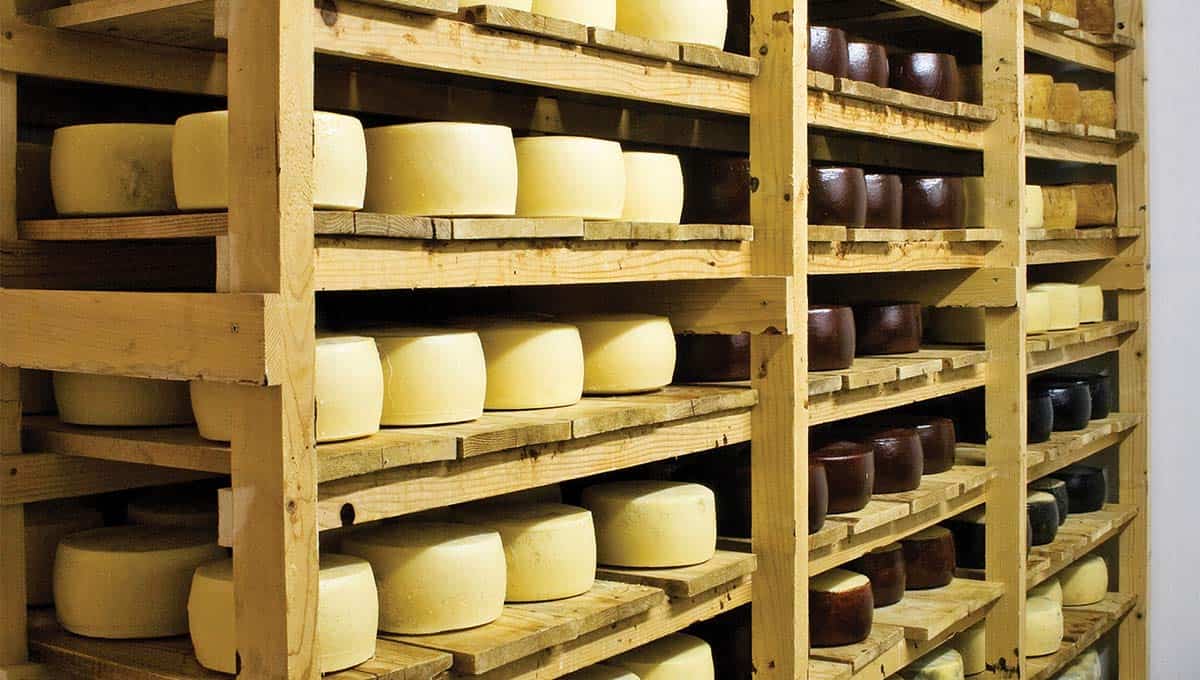

One of the key phases of cheese production is the ageing room where environmental conditions are critical to the quality of the final product. Close monitoring and control of temperature and humidity are required to provide stable, steady state conditions for the cheese.

It is in the monitoring of these tightly controlled ageing environments that Sanitary Designs specializes, helping its customers place high quality and consistent products on consumers’ tables.

The Challenge

Cheese producers have traditionally relied on inexpensive kit that is notoriously inaccurate and may require numerous manual checks, making it often difficult to know what is happening inside their ageing rooms from a temperature and humidity perspective.

Without proper measurement producers can’t see or react to fluctuations in conditions, a real problem in maintaining a genuine steady state environment. Steady state measurement is key in cheese production and it is the pursuit of it that prompts Neville and his team at CheezSorce/SDI to keep a constant look out for new equipment that can reliably deliver new insights.

Says Neville, “I am always surprised by the number of cheese makers who are okay “not knowing”. Knowing when you have dysfunctional gauges isn’t necessarily knowing much, but I can’t accept the “if the cheese looks good then it must OK” gauge!”

Getting Better Data

Following a recommendation, Sanitary Designs found and trialed Lascar’s EasyLog USB temperature and humidity data loggers in its consultancy work and immediately started to achieve not only greater accuracy in the recording of temperature and humidity, but also genuine 24 hour monitoring.

Neville was also impressed that this level of temperature, humidity and dew point accuracy could be achieved at a very reasonable cost point.

Completely separated from any existing temperature control system that a customer might have in place, the units also allowed SDI to bring genuine independence to a customer’s existing environmental monitoring system – validating the efficacy and accuracy of any control schemes put into action.

CheezSorce/SDI have been using the EasyLog devices since late 2013 and has now set up over 30 customers with control systems enabled by the Lascar loggers.

Says Neville, “Temperature and humidity are fundamentally hard to visualize and the Lascar devices are invaluable in helping us to educate our customers. Not only that but we have also learnt a lot ourselves. For instance, we have seen clearly from the data that we have collected that dew point is a far more important metric than anyone previously thought, and that by contrast relative humidity is less important than was assumed. These insights are already helping our customers develop better products.”

Better Products

SDI customers are already benefiting from the Lascar data loggers. One farmer that CheezSorce/SDI has advised reported that in 2014, despite processing the same volume of milk as in 2013, he was able to sell 300-500lb more cheese than in the previous year.

The farmer attributes that success directly to the SDI-enabled control put in place by SDI and in turn has enabled the farmer to invest in a new evaporator that will help achieve even better results in future. It was the Lascar data logger that was able to show the before and after performance of the room.

The greater education of customers enabled by the Lascar data loggers has also provided SDI with new opportunities to sell more services. With greater understanding of dew points inside ageing rooms, now customers are increasingly asking about the impact of dew points outside of the ageing room, proper sealing of rooms, vapor barriers, air changes and how to allow for general weather conditions outside. All of which means they are looking at getting more sophisticated controls from SDI.

The insights gained from the Lascar devices have also led SDI to develop a completely new control product. For the first time CheezSorce is offering a control that does not rely on a fixed temperature coil. Instead the company has developed a system that constantly modulates the temperature in ageing rooms in order to deliver the real stability that the cheese needs.

Not only does it give better stability but it also calls for less use of humidifiers and other such equipment – lowering the energy demands of ageing rooms. Of course the Lascar data loggers are providing the all-important validation that the new control is doing what it is meant to be.

“Lascar’s data loggers have been a revelation for me. These new state of the art ‘cool tools’ have enabled me to have real conversations with my customers about conditions in their ageing room that have just not been possible before. I recommend their capacitance type sensor, the EL-USB-2-LCD+, but we are also now making use of Lascar’s new WiFi enabled devices. This enables you to store information on the Cloud for access to your room’s statistics 24/7 from wherever you are. It even sends vital warnings so you can call the service guy before the cheese is lost! These improvements are making a huge difference to our business and Lascar have been impeccable since we started working with them.” Neville McNaughton, President, CheezSorce LLC and Sanitary Design Industries LLC.